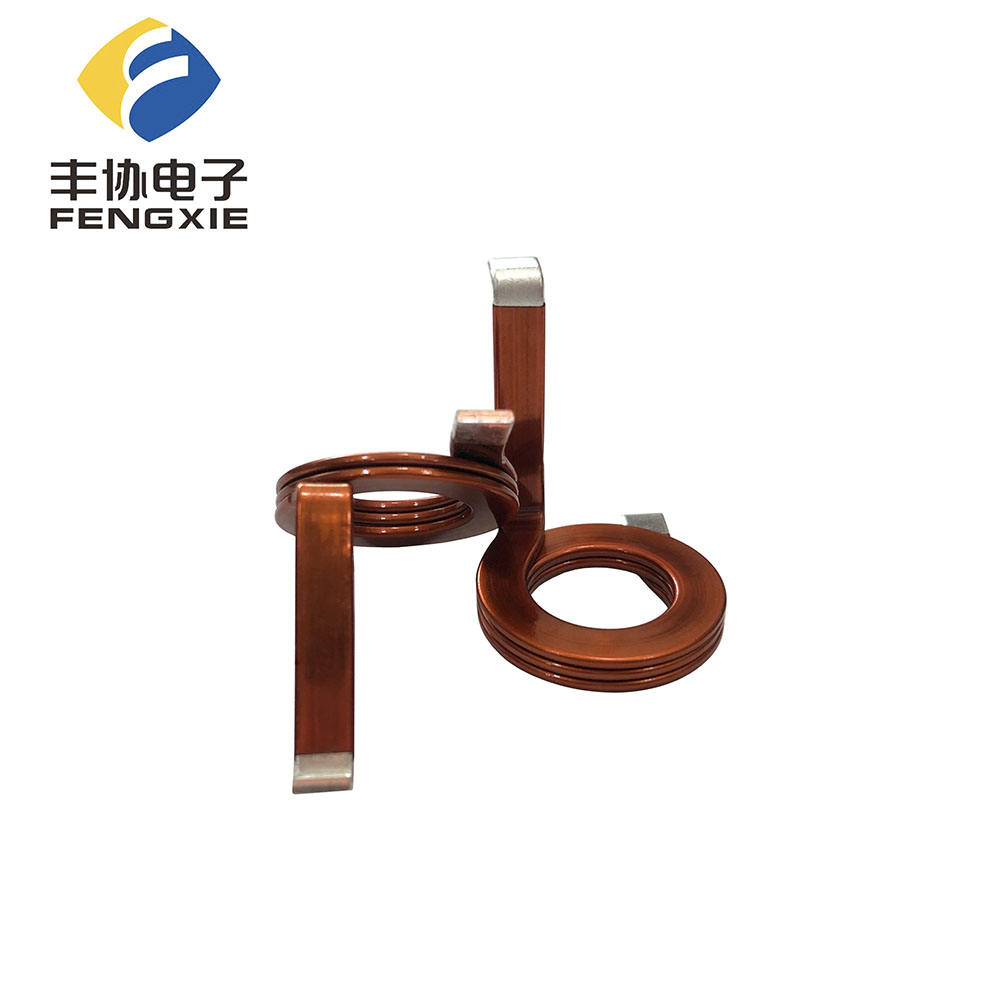

Planar Transformer Flat Wire Coil: Unlocking New Possibilities in Communication and Energy with Precision Winding

Publish Time: 2026-01-26

In today's rapidly developing high-frequency power electronics and renewable energy technologies, traditional magnetic components are struggling to meet the stringent requirements of miniaturization, high efficiency, and high reliability. The planar transformer flat wire coil, with its innovative structural design and superior electrical performance, is becoming a key component driving breakthroughs in cutting-edge fields such as communication, photovoltaic inverters, and energy storage systems. From flat wire toroidal inductors to photovoltaic inverter coils, these devices based on flat copper wire power inductor technology are redefining the performance boundaries of power magnetic components.1. Low Profile and Efficient Heat Dissipation: Ideal for High-Frequency ApplicationsThe planar transformer flat wire coil is wound with flat copper wire, which has a rectangular cross-section, providing a larger surface area and shorter current path compared to traditional round wire. This planar flat wire design not only significantly reduces skin effect and proximity effect losses at high frequencies but also achieves an extremely low profile height, perfectly suited for the space-constrained modern electronic devices. Meanwhile, the flat structure increases the contact area with the PCB or heat sink, significantly improving heat conduction efficiency and ensuring stable operation in high-power-density scenarios such as high-frequency planar transformers and DC-DC converter modules, effectively preventing overheating failure.2. Reliable Guardian in Extreme EnvironmentsFaced with challenges such as large diurnal temperature variations in outdoor photovoltaic power plants and high temperatures and humidity in industrial equipment, this type of coil exhibits excellent wide-range temperature stability. Its materials and packaging processes undergo rigorous selection, maintaining stable inductance and reliable insulation performance within an extreme temperature range of -45℃ to +125℃. Whether deployed in solar energy systems in deserts or switched power supplies installed in communication base stations, it can operate without failure for extended periods, providing robust protection for critical infrastructure.3. High Power Density and Precision Winding: A Dual Leap in Efficiency and PerformanceIn renewable energy systems, such as PV inverters and energy storage inductors (PV units), energy conversion efficiency directly affects power generation revenue and system lifespan. Planar flat wire coils achieve highly symmetrical magnetic circuits and minimized leakage inductance through precise winding structures—such as an optimized 2.75-turn configuration—significantly reducing AC losses and improving core utilization. This design enables power inductor flat wire PV inverters to output higher power within a compact size, helping inverters achieve conversion efficiencies of >98%. Similarly, in multilayer coil solar inverters, multi-layer flat winding stacking further increases power density, meeting the dual demands of miniaturization and high performance for residential and commercial energy storage systems.4. Diverse Application Scenarios: From Communication to Green EnergyThanks to their high-frequency, high-efficiency, and high-reliability characteristics, planar flat wire coils have been widely used in multiple high-tech fields. In communication equipment, they serve as high-frequency choke coil inverters to filter switching noise and stabilize power rails; in 5G base station power modules, inductive choke photovoltaic structures effectively suppress electromagnetic interference and ensure signal integrity. In the new energy sector, flat wire coil solar energy systems have become core magnetic components of mainstream inverters, supporting the global energy transition.From flat copper wire power inductors to photovoltaic inverter coils, planar transformer flat wire coils are paving new paths for high-frequency power electronics through the integration of materials science and precision manufacturing. They are not merely components, but carriers of efficiency, reliability, and sustainable development. With the advancement of carbon neutrality goals and the expansion of digital infrastructure, these high-performance magnetic components will continue to empower green energy and smart communications, carrying the surging pulse of the future energy and information world with their "flat bodies."