How can a DC converter power inductor coil significantly improve power conversion efficiency through low DC resistance design?

Publish Time: 2026-02-03

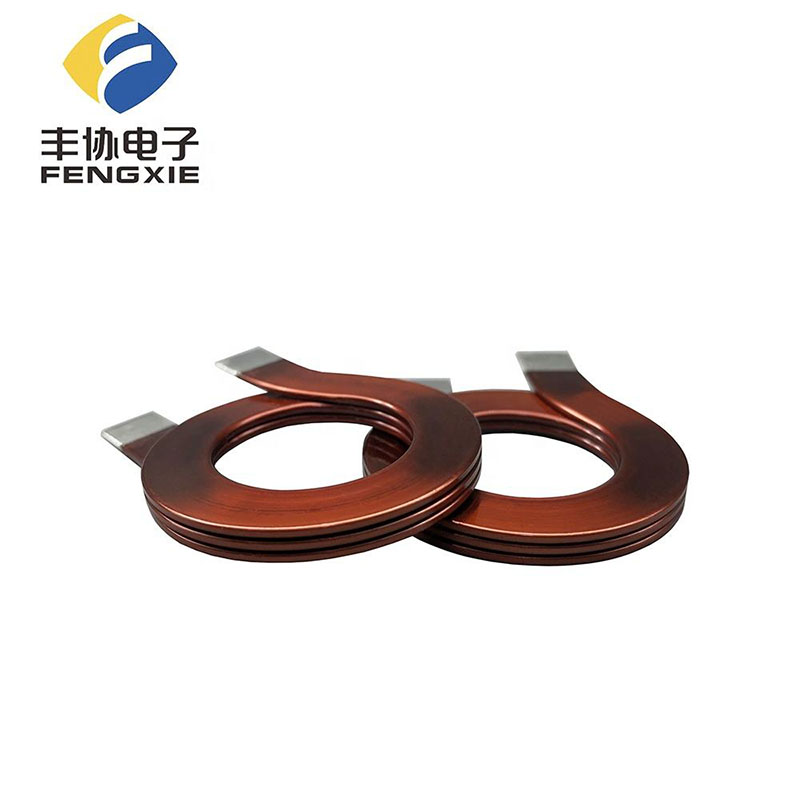

In modern electronic devices with stringent requirements for energy efficiency, size, and reliability, the DC-DC converter, as the core power management unit, directly determines the overall power consumption and thermal stability of the device. Although small in size, the DC converter power inductor coil plays a crucial role in energy storage, filtering, and current smoothing. Low DC resistance design has become a key technological path to improve conversion efficiency.1. Low DCR: Reducing Copper Losses, Directly Improving Energy EfficiencyDuring operation, the inductor coil of a DC converter continuously carries a large current. The coil's own DC resistance causes significant copper losses, which are dissipated as heat, reducing overall efficiency and causing temperature rise, affecting system stability. Traditional inductors using thin-diameter enameled wire or multi-layer winding have high resistance, leading to particularly severe losses under high loads. Low DCR design significantly reduces resistance by increasing the conductor cross-sectional area, shortening the winding path, or using multi-strand stranded wire.2. Material and Process Synergy: Engineering Breakthroughs for Low DCRAchieving low DCR is not simply a matter of thickening the wires; it also requires balancing inductance, saturation current, size, and cost. To this end, manufacturers are constantly innovating in materials and processes:High-purity oxygen-free copper wire is widely used due to its superior conductivity compared to ordinary copper;Flat copper strip windings or one-piece molded metal alloy structures maximize conductor fill factor and reduce ineffective length caused by gaps;Optimized winding layout avoids additional resistance caused by crossover;In surface mount inductors, the integrated design of internal terminals and coils further shortens the current path and reduces contact resistance.These technologies work synergistically, enabling modern power inductors to achieve milliohm-level DCR within tiny packages while maintaining high saturation current and good heat dissipation.3. System-Level Benefits: Comprehensive Improvement in Efficiency, Temperature Rise, and ReliabilityThe advantages of low DCR go far beyond improved efficiency figures. First, lower temperature rise means a milder operating environment for the inductor and surrounding components, extending the lifespan of the entire power module. Second, in battery-powered devices, every 1% increase in efficiency translates to longer battery life. Third, in high-frequency switching power supplies, low DCR helps maintain stable output voltage ripple and improves dynamic response. Especially in high-power-density scenarios such as multi-phase VRMs or server power supplies, the cumulative DCR effect of dozens of inductors is extremely significant; using low-DCR products can substantially reduce total system power consumption and heat dissipation costs.

The low DC resistance design of the DC converter power inductor coil is a crucial fulcrum for the evolution of power supply technology towards higher efficiency and miniaturization. It is not only a comprehensive achievement of materials and processes but also a key lever for optimizing system energy efficiency. With the explosive growth of high-power applications such as 5G communication, AI servers, and new energy vehicles, the demand for low-DCR power inductors will continue to increase.