Planar Transformer Flat Wire Coil: A Revolution in Low-Profile Magnetic Components for the High-Frequency Era

Publish Time: 2025-12-29

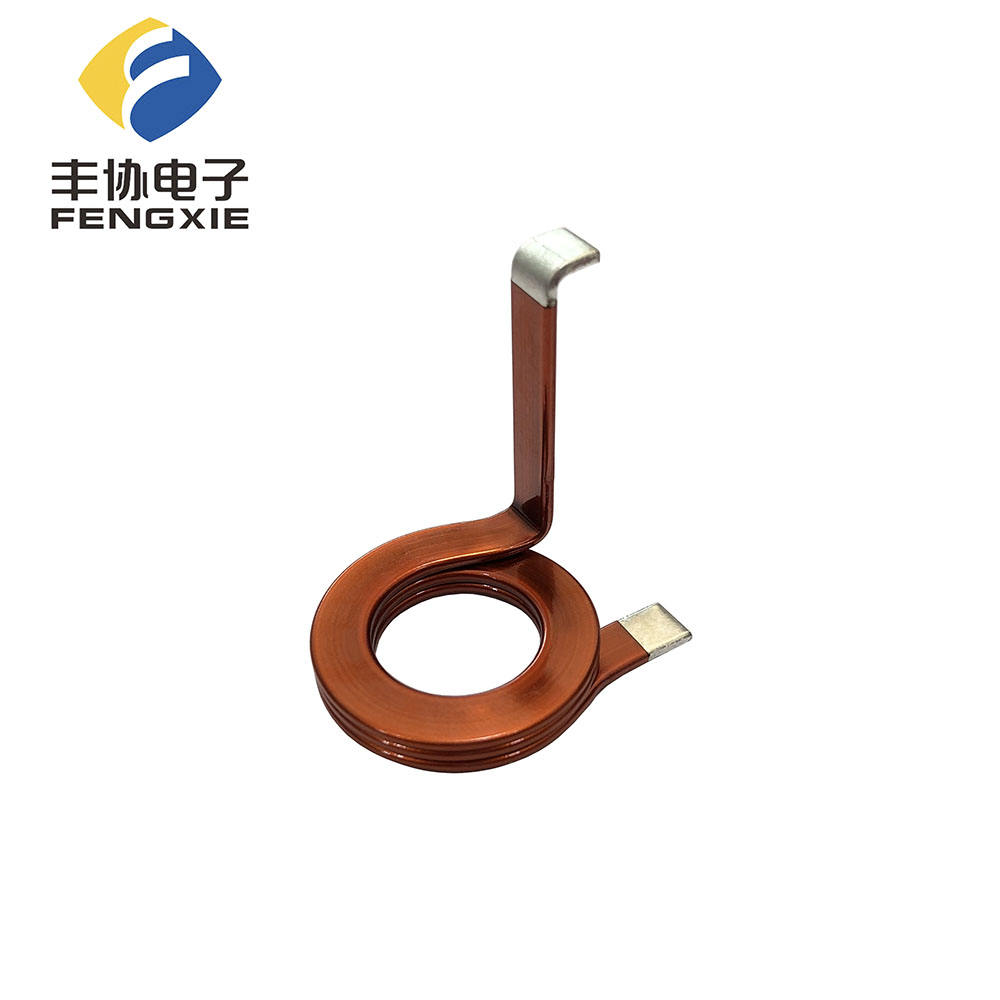

In the wave of evolution towards higher frequencies, miniaturization, and higher efficiency in modern power electronics systems, traditional magnetic components are struggling to meet increasingly stringent design requirements. Planar transformers, with their unique structural advantages, are becoming a key technology platform in the field of high-frequency power conversion. The core component—the planar transformer flat wire coil—is leading the innovation of magnetic components with its superior electrical, thermal, and mechanical properties.1. Planar Flat Wire Design: A Perfect Fusion of Low Profile and Efficient Heat DissipationThe planar transformer flat wire coil uses flat copper wire instead of traditional round wire windings, achieving an extremely low profile height through edgewise winding storage technology. This structure not only significantly reduces the vertical space occupied by the component but also significantly increases the contact area between the conductor and the PCB or heat sink. Under high-frequency switching conditions, eddy current effects and proximity effects cause traditional coils to overheat severely, while the large surface area of the flat wire effectively reduces current density and enhances the heat conduction path, thus achieving excellent heat dissipation performance.This characteristic makes it particularly suitable for size-sensitive and thermally demanding applications, such as 5G communication base station power supplies, automotive DC-DC converters, and server power modules. Simultaneously, the low-profile design enables multi-layer stacking integration, giving rise to the Multilayer Coil Energy System architecture, achieving higher power density within a limited space.2. Wide Temperature Range Stability: Reliable Operation in Extreme EnvironmentsModern electronic systems often need to operate stably in harsh environments, from extremely cold outdoor communication equipment to high-temperature industrial converters. Planar transformer flat wire coils, through optimized material selection and packaging processes, maintain stable electrical parameters over a wide temperature range of -45℃ to +125℃. Their low thermal resistance structure, combined with a high thermal conductivity insulating medium, effectively suppresses the impact of temperature rise on core performance, avoiding efficiency degradation or control instability caused by thermal drift.This reliability is especially important for renewable energy systems—which are exposed to the outdoors year-round, experiencing large diurnal temperature variations, placing extremely high demands on the weather resistance of magnetic components. The wide temperature stability of flat coils ensures the long-term safe operation of the energy conversion chain, providing solid support for the efficient grid connection of green energy.3. High Power Density: Small Size, High Energy ReleaseThanks to its precise planar layout and efficient magnetic circuit design, flat coils achieve superior performance within a compact size, with a power density far exceeding that of traditional wound transformers. Its high-current flat wire energy capability supports high-current transmission, while reducing parasitic parameters improves conversion efficiency at high frequencies.In switching power supplies and DC-DC converter modules, this high power density directly translates into higher system integration and lower material costs. For example, in data center server power supplies, planar transformers using flat coils can reduce the size of magnetic components by more than 40%, while improving efficiency by 1–2 percentage points, resulting in annual power savings of thousands of kilowatt-hours. Furthermore, this characteristic also makes it an ideal carrier for magnetic energy storage inductors and high-power choke coil storage, playing a crucial role in high-dynamic load scenarios such as pulsed power and fast charging of electric vehicles.4. Precision Winding Structure: Optimized Magnetic Efficiency and Reduced AC LossesThis product employs an optimized 2.75-turn configuration, combined with computer-aided winding technology, achieving micron-level control over turn spacing and layer alignment. This precision winding structure effectively suppresses AC losses at high frequencies, particularly excelling in the hundreds of kHz to several MHz frequency range. Compared to traditional random winding, its leakage inductance is reduced by more than 30%, and the coupling coefficient approaches the ideal value, significantly improving magnetic energy transfer efficiency.This design is not only suitable for standard high-frequency planar transformers but can also be extended to advanced energy storage applications. For example, in the exploratory Superconducting Coil SMES, although the superconducting material itself has no resistance, conventional leads and interfaces still exhibit losses. Using low-loss flat coils as transition connections or auxiliary inductors can improve overall system efficiency. While toroidal superconducting coils possess excellent magnetic field confinement capabilities, their manufacturing is complex; in contrast, planar flat coils, with their advantages of low cost and ease of integration, are more practical in low-to-medium power magnetic energy storage applications.5. Diverse Application Scenarios: Comprehensive Coverage from Communications to Renewable EnergyLeveraging the aforementioned characteristics, planar transformer flat wire coils have been widely applied in several high-growth sectors:In communication equipment, they provide efficient, low-noise power isolation for 5G AAUs (Active Antenna Units) and optical modules;In switching power supplies and DC-DC converter modules, they support high-reliability power supply for servers, industrial PLCs, and medical equipment;In renewable energy systems, they serve as key magnetic components in photovoltaic micro-inverters and energy storage converters, improving energy conversion efficiency;In emerging inductor coil power storage architectures, they act as high-response energy buffer units, participating in grid frequency regulation and instantaneous power compensation.In the future, with the further development of flat wire coil energy storage technology, flat coils are expected to evolve from "passive magnetic components" to "active energy storage units," collaborating with supercapacitors and battery systems to build hybrid energy storage networks, providing more flexible energy management solutions for smart grids and electric transportation.