How can energy storage inductor coils achieve efficient power processing in space-constrained portable devices?

Publish Time: 2025-12-23

In today's rapidly developing world of highly integrated electronic products such as smartphones, wearable devices, drones, and portable medical instruments, internal space is extremely limited, placing stringent demands on core components to be "smaller, stronger, and more stable." As a key passive component in power management and energy conversion systems, energy storage inductor coils are overcoming the traditional contradiction between size and performance through material innovation, structural optimization, and precision manufacturing processes. Within an ultra-thin space of only 6.0mm in height, they achieve high energy density, low loss, and reliable operation over a wide temperature range, becoming the "invisible engine" for efficient power processing in modern portable devices.

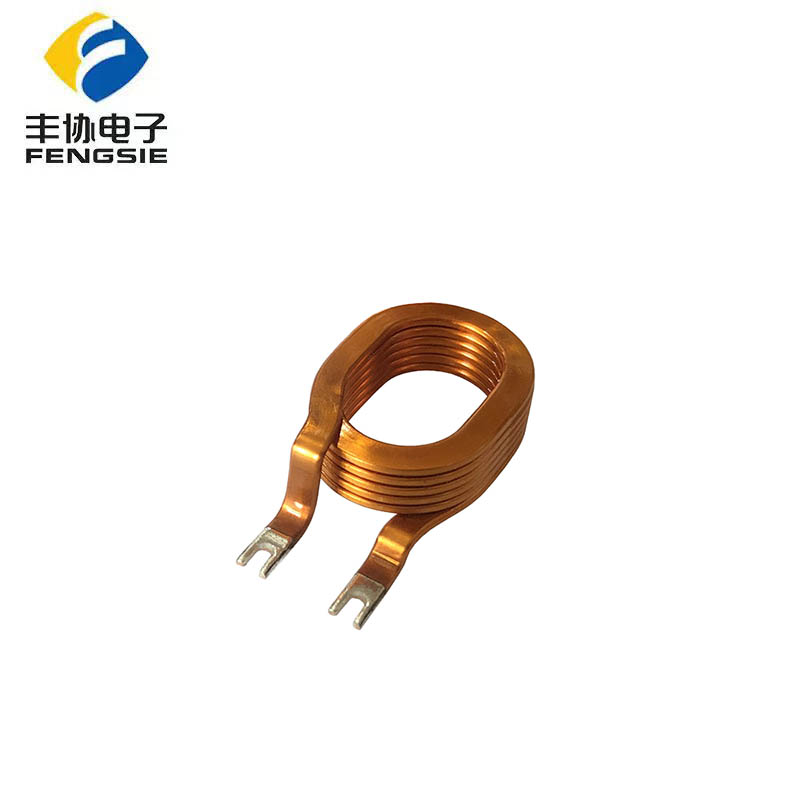

I. Ultra-thin High Energy: Synergistic Breakthrough of Flat Wire and Edgewise Winding TechnologiesTraditional round wire wound inductors are susceptible to the "skin effect" and "proximity effect" under high-frequency, high-current conditions, leading to increased AC resistance and accelerated temperature rise. This energy storage inductor employs copper flat wire and edgewise winding technology, tightly arranging the conductors with their wide sides perpendicular to the magnetic core direction. This design significantly increases the effective cross-sectional area of the conductors, substantially reduces high-frequency impedance, and simultaneously enhances current carrying capacity—the so-called High Current Flat Wire Energy characteristic.Combined with an ultra-thin package with a maximum height of only 6.0mm, this inductor achieves extremely high energy density, making it particularly suitable for thickness-constrained TWS earphone charging cases, ultra-thin laptop motherboards, or AR/VR headsets. Its 5.75-turn precision winding structure has been optimized through electromagnetic field simulation to ensure the shortest magnetic flux path and minimal leakage inductance, thereby achieving optimal efficiency for inductor-coil power storage within a small volume.II. Multilayer Integration and Core Optimization: Building a Multilayer Coil Energy SystemTo further enhance energy storage capacity within a limited planar area, this inductor adopts the Multilayer Coil Energy System design concept. By combining multi-layered flat coil stacks with high-permeability, low-loss ferrite or metal alloy cores, a compact magnetic energy storage inductor is formed. The core often employs a closed toroidal structure, which not only ensures a closed magnetic circuit and extremely low EMI radiation but also effectively suppresses external magnetic field interference, guaranteeing the normal operation of surrounding sensitive circuits.It is worth noting that although a cryogenic cooling system is not used, its design philosophy draws inspiration from the extreme pursuit of magnetic flux density and thermal management in Superconducting Coil SMES —by optimizing the core saturation characteristics and winding distribution, the inductor remains linear even near saturation current, preventing the DC-DC converter from shutting down due to inductor failure.III. Reliable Operation Over a Wide Temperature Range: From Extremely Cold Outdoors to High-Temperature Fast Charging ScenariosPortable devices operate in complex and varied environments: in winter, outdoor temperatures can reach below -30°C, while during fast charging, local temperatures can soar to over 100°C. This inductor supports a wide operating temperature range of -45℃ to +125℃, thanks to the following key features:The flat copper wire itself has excellent thermal conductivity, allowing heat to dissipate rapidly laterally along its wide surface;The core material undergoes high-temperature aging screening, resulting in a high Curie point and low permeability temperature drift;The encapsulation uses high-temperature resistant epoxy resin or LCP (liquid crystal polymer), ensuring the structure does not crack or delaminate during thermal cycling.This characteristic makes it particularly reliable in power tools, outdoor handheld terminals, and automotive portable devices.IV. High-Efficiency Heat Dissipation and Low Loss: Supporting High Power Choke Coil Storage ApplicationsIn battery management systems and synchronous buck DC-DC converters, inductors need to continuously withstand pulse currents of several amperes or even tens of amperes. This product, through its High Power Choke Coil Storage architecture and the low ACR advantage of flat wire, keeps power losses in the milliwatt range. Meanwhile, its flat surface and low thermal resistance allow for direct mounting on large copper foil areas of a PCB, utilizing the PCB as a heat dissipation channel for passive and efficient heat dissipation, eliminating the need for additional fans or heat sinks.V. Application Scenarios: From Chip-Level Power Supplies to Micro Energy Storage SystemsLeveraging the above advantages, this compact energy storage inductor has been widely used in five core areas:Portable electronic devices: Providing stable, low-noise power to SoCs and GPUs;Power Management Circuits (PMICs): Achieving efficient multi-channel voltage conversion;Battery Management Systems: Filtering and storing energy in the charging and discharging circuit to protect the battery cells;DC-DC Converters: Serving as the main energy storage component, supporting high switching frequency designs;Micro energy storage systems: Such as energy buffer units in USB-PD fast chargers and solar-powered portable power supplies.Although small, the energy storage inductor coil is the "energy hub" of modern power electronic systems. Through cutting-edge technologies such as Flat Wire Coil Energy Storage, Edgewise Winding, and Multilayer Integration, it successfully achieves high power, high efficiency, and high reliability energy throughput within a millimeter-scale space. In the future, as GaN/SiC wide bandgap devices drive further increases in switching frequencies, the demand for ultra-thin, low-loss, and high-saturation inductors will become even more urgent. This energy storage inductor, designed specifically for extreme space constraints, is driving the efficient operation of the portable electronics world with its "invisible precision."