Thermal Design Overlooked? How Can Energy Storage Inductors Achieve Efficient Heat Dissipation and Temperature Uniformity?

Publish Time: 2025-12-15

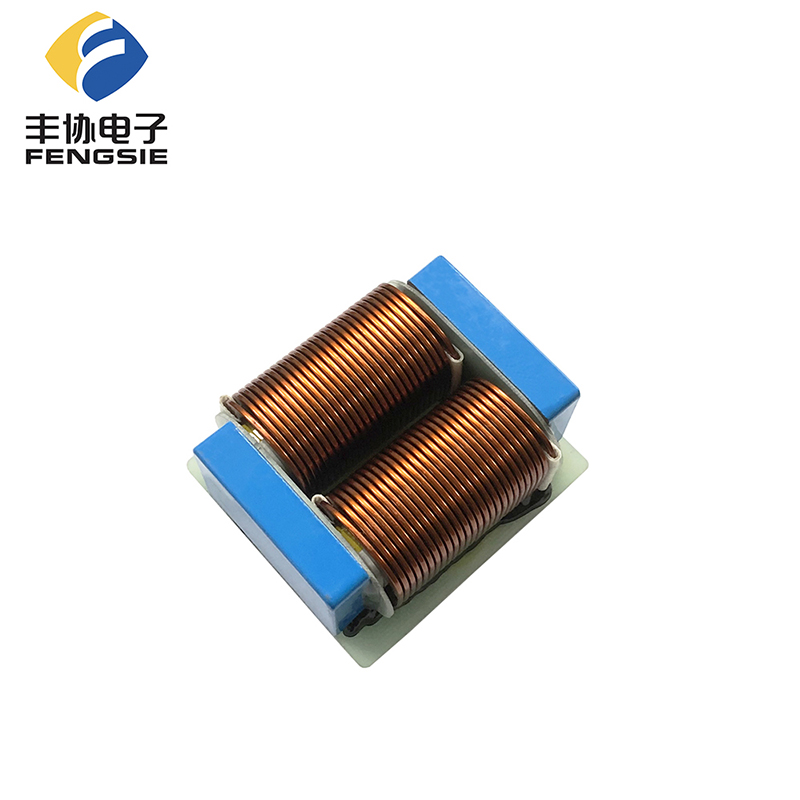

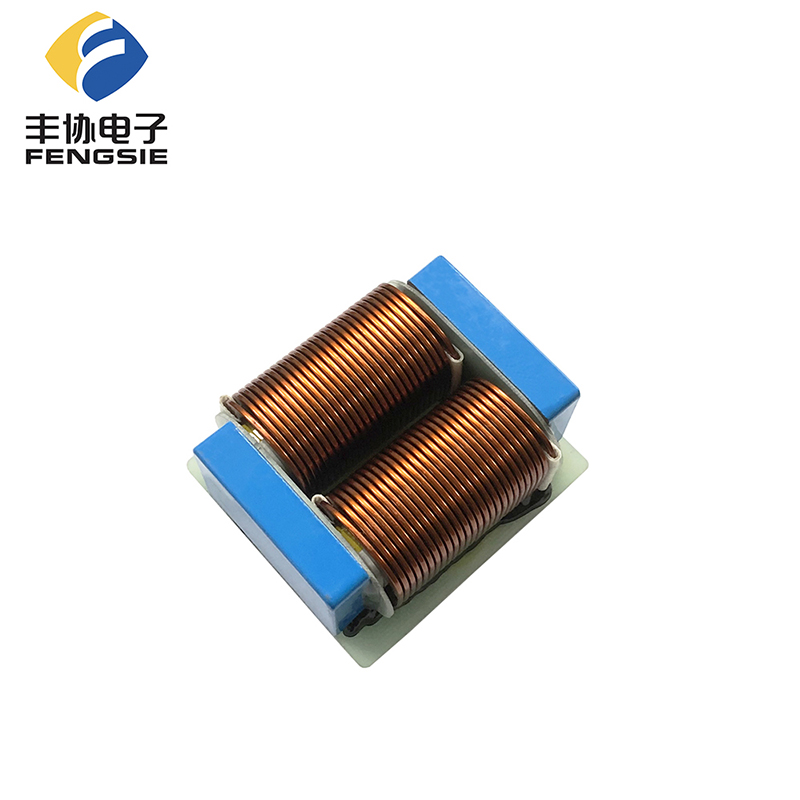

In high-power power electronic systems such as new energy power generation, electric vehicle fast charging, and data center power supplies, energy storage inductors play a crucial role in energy storage, current smoothing, and electromagnetic interference suppression. However, as system power density continues to increase, inductors face severe challenges under high current and even instantaneous overload conditions—not only may the magnetic core fail due to saturation, but more seriously, internal heat accumulation can lead to uncontrolled temperature rise, accelerating insulation aging, causing performance drift, and even catastrophic failures. Therefore, efficient thermal management has gone from an "optional" to a "must-have." How to maintain a low temperature and uniform temperature field in energy storage inductors under full load operation has become a core issue in high-end product design.I. Starting with the "Heat Source": Precisely Controlling Loss GenerationTo solve the heat dissipation problem, the heat source itself must first be reduced. In high-current applications, winding copper losses are the main heat source. Traditional round wire windings are affected by the skin effect at high frequencies, resulting in a sharp reduction in effective conductive area and a dramatic increase in resistance. Therefore, modern high-performance inductors commonly employ Copper Flat Wire Energy Coil technology. The flat cross-section not only increases the conductor surface area and reduces AC resistance, but its regular arrangement also improves the winding fill factor, reducing thermal resistance caused by gaps. This High Current Flat Wire Energy design allows the inductor to maintain a low temperature rise even when carrying hundreds of amperes of current, laying the foundation for subsequent heat dissipation.