In automotive power systems, how do EV charging pile inductors ensure efficient energy conversion and stable output?

Publish Time: 2025-12-12

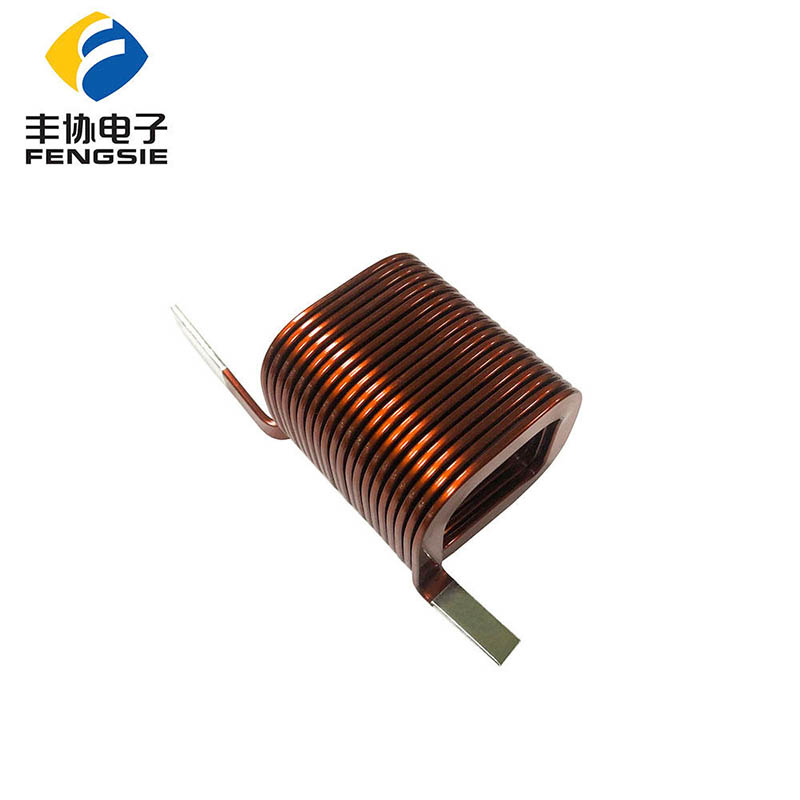

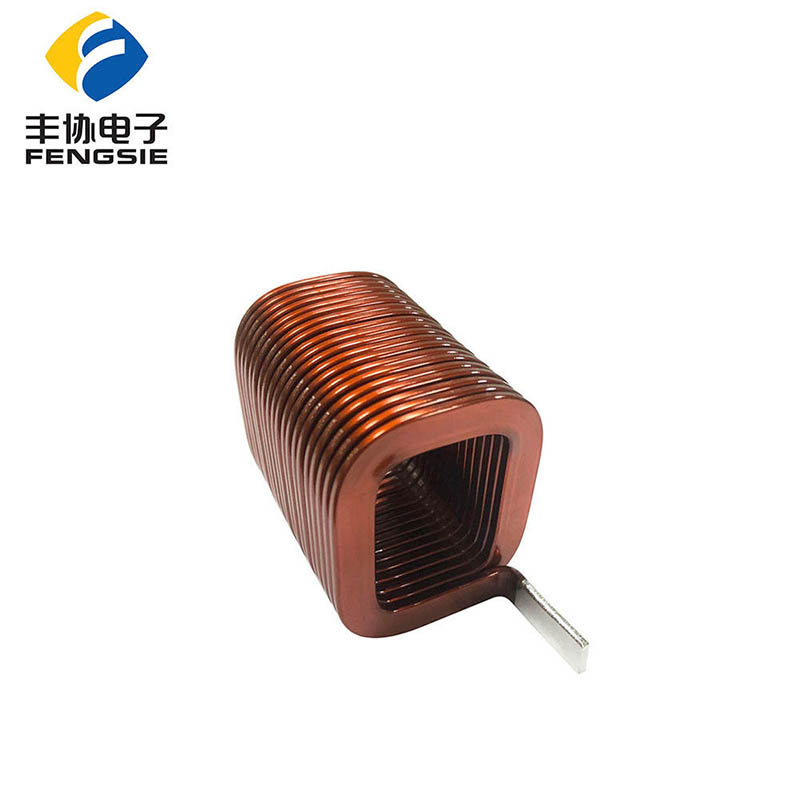

With the rapid development of the global new energy vehicle industry, electric vehicles (EVs) and their supporting infrastructure—especially EV charging piles—are undergoing unprecedented technological upgrades. As a key magnetic component in the core power module of a charging pile, the inductor plays a crucial role as an "invisible guardian" in energy conversion, filtering, voltage regulation, and electromagnetic compatibility. EV charging pile inductors must simultaneously meet stringent requirements such as high current carrying capacity, wide temperature range operation, low loss, and strong heat dissipation.1. High Power Performance: The Cornerstone for Handling Extreme Current DemandsModern DC fast charging piles need to deliver hundreds of amperes of current to the battery in a short time. In this process, the DC-DC converter and PFC module undertake the task of converting the high-voltage DC bus to the battery's adaptive voltage, and the inductor is the energy storage and filtering unit in these topologies.Inductors specifically designed for EV charging use high-saturation flux density core materials and are combined with a 20-turn precision multi-layer winding structure, significantly improving inductance stability and DC bias resistance. Even under peak current surges, the inductance value will not drop sharply, thus avoiding control loop instability or output voltage fluctuations. This high-power performance ensures that energy transfer from the grid to the battery is both fast and controllable, a technological prerequisite for realizing the vision of "5 minutes of charging for 200 kilometers of range."2. Wide Temperature Range Stability: Reliable Operation from -45℃ to +125℃Charging stations are often deployed outdoors, facing extreme climates such as extreme heat, cold, and high humidity. Ordinary inductors may become brittle and crack at low temperatures, and are prone to problems such as core aging and winding insulation failure at high temperatures. Inductors specifically designed for the automotive electronics industry ensure full-temperature reliability through the following design features:High-temperature resistant insulated enameled wire: The windings use flat copper wire with insulation class H or higher, combined with Edgewise Winding technology to improve space utilization and heat conduction efficiency;Thermal expansion matching packaging: The thermal expansion coefficients of the outer shell and internal filling material are precisely matched to prevent mechanical stress during temperature cycling;Compliant with AEC-Q200 standards: Some high-end products have passed automotive-grade passive component reliability certification, ensuring long-term stable operation under cold start conditions of -45℃ or full load conditions of +125℃.This wide temperature tolerance makes the inductor an uninterrupted energy bridge connecting the power grid and electric vehicles.3. Optimized heat dissipation management: The art of thermal balance under high-power cyclingHigh-power charging means continuous Joule heating. If the heat cannot be dissipated in time, the inductor temperature will rise excessively, increasing copper and iron losses, creating a vicious cycle. To address this, advanced charging pile inductors employ an integrated heat dissipation structure design:Metal base directly connected to PCB: The inductor's bottom integrates a high thermal conductivity metal substrate, which can be directly soldered to a power board with heat dissipation vias for rapid heat conduction;Flat wire winding: Compared to traditional round wire, flat copper wire has a larger surface area and lower skin effect, resulting in lower resistance and less self-heating under high frequency and high current;Forced air cooling/liquid cooling compatible structure: Some modular inductors support collaborative operation with the charging pile's liquid cooling system, further enhancing heat dissipation.Through these measures, even in high-intensity usage scenarios involving continuous multi-vehicle fast charging, the inductor can maintain temperature rise within a safe range, ensuring long-term efficient system operation.4. Precision winding and low-loss design: Key to improving overall conversion efficiencyEvery 1% increase in energy conversion efficiency translates into considerable energy savings for large charging stations. The charging pile inductor minimizes total losses through the synergistic optimization of a 20-turn precision multilayer winding and a low-loss magnetic core:Litz Wire or flat wire application: In high-frequency switching scenarios, Litz wire or multi-strand parallel-wound flat wire is used to effectively suppress skin and proximity effects;Precise air gap control: A micron-level air gap is incorporated into the magnetic core to prevent magnetic saturation and reduce hysteresis losses;Low DCR design: DC resistance is reduced by 8%~12%, which can improve system efficiency by 2~3 percentage points in DC-DC power modules.This meticulous loss control not only extends equipment lifespan but also helps charging piles meet increasingly stringent energy efficiency regulations.5. Wide Range of Applications: Covering the Entire Supply Chain from Charging Piles to Vehicle SystemsThanks to the above characteristics, this type of high-performance inductor has been widely used in several key areas:Electric Vehicle Charging Stations and Fast Charging Piles: As a core component of PFC and DC-DC modules;Automotive Power Systems: Used for power factor correction and isolation conversion in OBCs;DC-DC Converters for Electric Vehicles: Achieving efficient energy conversion between high-voltage battery packs and 12V/48V low-voltage systems;Energy Storage and Charging Systems: Performing bidirectional energy dispatching functions in integrated photovoltaic-energy storage and charging power stations.Furthermore, in subcategories such as Flat Wire Inductor Automotive, High Current Flat Wire Coil, and Toroidal Inductor Automotive, this inductor has become a key product for automotive electronics suppliers due to its high current density and EMI suppression capabilities.In the wave of electric mobility, the EV charging pile inductor, though small, is a crucial link in ensuring the "efficient, safe, and stable" flow of electrical energy. It integrates the automotive electronics industry's pursuit of ultimate reliability, efficiency, and environmental adaptability, silently supporting the successful completion of every fast charge through high-power design, wide-temperature-range materials, intelligent heat dissipation, and precision winding technology.