In today's rapidly developing power electronics, new energy systems, and high-frequency communication technologies, inductors, as core components for energy storage, filtering, isolation, and impedance matching, directly determine the efficiency and stability of the entire system. Among numerous inductor structures, the double-wound coil, with its unique dual-winding design, has become the "dual king" for achieving both high-efficiency energy transfer and flexible circuit configuration. It is widely used not only in RF transformers, impedance matching networks, and wireless communication systems, but also plays an irreplaceable role in photovoltaic energy storage, high-power converters, and advanced magnetic energy storage technologies.

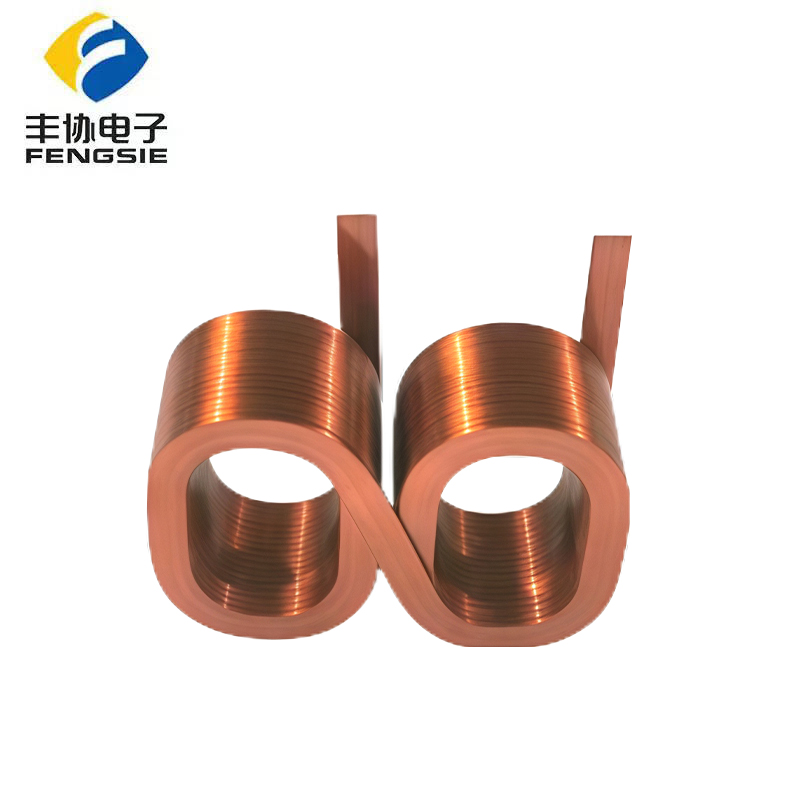

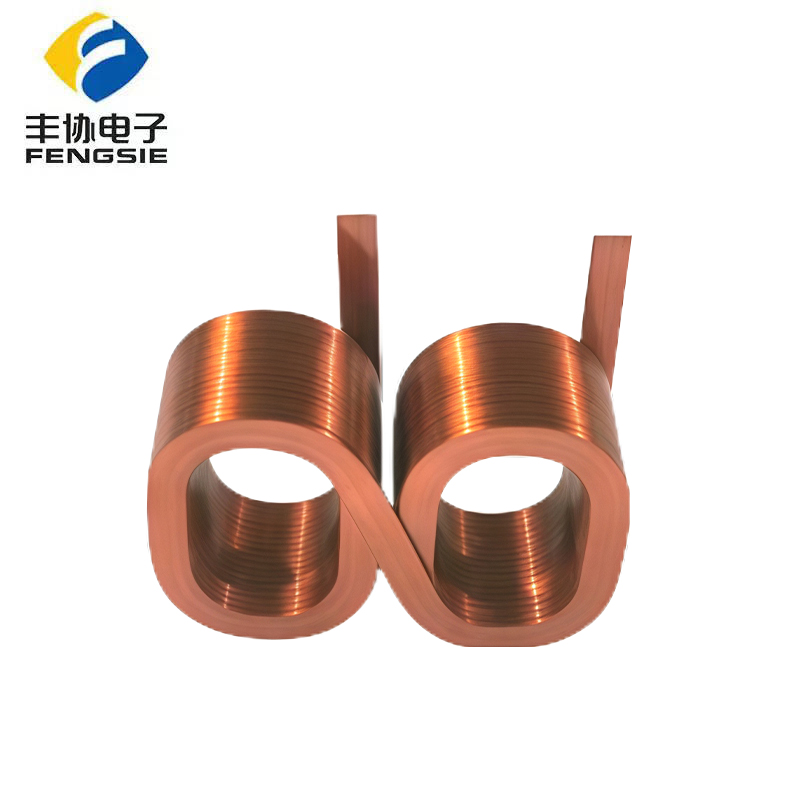

I. Structural Advantages of Double-Wound Coils: Multifunctional Integration from Coupling to IsolationA double-wound coil is essentially composed of two independent but magnetically coupled windings sharing a single magnetic core. This structure gives it the dual functions of a transformer and an inductor. By precisely controlling the turns ratio, winding method, and relative position of the two windings, various electrical characteristics such as voltage transformation, current isolation, common-mode rejection, and bidirectional energy flow can be achieved.In high-frequency applications, such as 5G base stations or Wi-Fi 6E RF front-ends, double-wound coils are often used as baluns or impedance matching transformers to ensure efficient signal transmission between ports with different impedances and minimize reflection losses. Their low distributed capacitance and high self-resonant frequency characteristics allow them to maintain excellent performance even in the GHz band.In power electronics, double-wound coils are commonly found in topologies such as LLC resonant converters and bidirectional DC-DC converters. For example, in photovoltaic energy storage systems, they enable efficient bidirectional energy flow between the photovoltaic array and the battery: excess energy is charged into the battery during the day and released in the reverse direction at night or on cloudy days, relying entirely on the magnetic coupling between the two windings for energy transfer, eliminating the need for additional switching devices and significantly improving system efficiency and reliability.II. Low Iron Loss and High Reliability: Synergistic Innovation in Materials and ProcessesTo meet high efficiency requirements, double-wound coils generally use low-loss soft magnetic materials as the core, such as ferrite, amorphous alloys, or nanocrystalline materials. These materials exhibit extremely low hysteresis and eddy current losses at high frequencies, with controllable temperature rise even at operating frequencies from tens of kHz to MHz.Simultaneously, the coil structure itself has been meticulously optimized. In recent years, flat copper wire windings have gained popularity due to their superior skin effect suppression capabilities. Compared to traditional round wire, flat wire has a larger surface area for the same cross-sectional area, effectively reducing high-frequency AC resistance. Especially in high-current flat coil energy storage and copper flat wire energy coil designs, flat wire windings can carry higher current densities, reduce heat generation, and increase power density.Furthermore, the edge-winding process further optimizes the space utilization and heat dissipation performance of flat wire coils. This process allows the wide face of the flat wire to be wound perpendicular to the magnetic core surface, which not only reduces leakage inductance but also enhances interlayer heat conduction, making it particularly suitable for high-current applications such as high-power choke coil energy storage.

III. Towards Advanced Magnetic Energy Storage: From Multilayer Coils to Superconducting CoilsWith increasing demands for energy density and response speed, the concept of double-wound coils is extending to more advanced magnetic energy storage inductors. In this field, several novel coil structures have emerged:Multilayer Coil Energy Systems (MCS) achieve higher inductance and energy storage capacity within a limited volume through three-dimensional stacked windings, making them suitable for compact energy storage converters.Toroidal Superconducting Coils (TSCs) represent the pinnacle of magnetic energy storage—utilizing the zero-resistance properties of superconducting materials at low temperatures, they can store megajoules of energy with near-lossless operation, finding wide application in grid frequency regulation, pulse power supplies, and other scenarios.While Superconducting Coil SMES (Superconducting Magnetic Energy Storage) systems are expensive, their millisecond-level response and near-100% round-trip efficiency make them strategically valuable in critical infrastructure.It is noteworthy that even in these cutting-edge systems, the dual-winding concept persists. For example, some SMES devices employ a dual-winding structure to achieve electrical isolation between the charging and discharging circuits, or to use secondary windings for condition monitoring to ensure safe system operation.IV. Key Role in Photovoltaic Energy Storage SystemsIn distributed photovoltaic + energy storage systems, the double-wound coil is the "hub" connecting the DC bus, battery pack, and inverter. Taking a typical bidirectional isolated DC-DC converter as an example, its core is a high-performance double-wound coil:The primary winding connects to the photovoltaic/DC bus, and the secondary winding connects to the battery;Through phase-shift control, energy can flow efficiently in both directions;The transformer's isolation characteristics ensure the safety of personnel and equipment;Low iron loss and low copper loss design enable the overall efficiency to exceed 98%.Furthermore, the double-wound coil can integrate common-mode inductance, suppressing high-frequency noise conduction along battery cables and improving EMC performance. Its robust mechanical structure (typically encapsulated in epoxy or metal casing) further withstands outdoor vibration, moisture, and temperature shocks, ensuring reliable operation for over 25 years.From microwatt-level signal processing in radio frequency communication to kilowatt-level energy dispatch in photovoltaic energy storage, and megajoule-level energy buffering in superconducting magnetic energy storage, the double-wound coil, with its structural flexibility, high energy transfer efficiency, and operational reliability, permeates multiple dimensions of modern electrical engineering. It is not merely a passive component, but also a "smart valve" for energy flow. In the wave of carbon neutrality and digitalization, this "dual-role king" will continue to drive the deep integration of green energy and smart power systems with innovation, injecting a continuous stream of magnetic energy into the future energy world.