How to maintain inductance stability and suppress saturation in EV power inductor coils used in automotive DC-DC converters over a wide input voltage range?

Publish Time: 2026-02-09

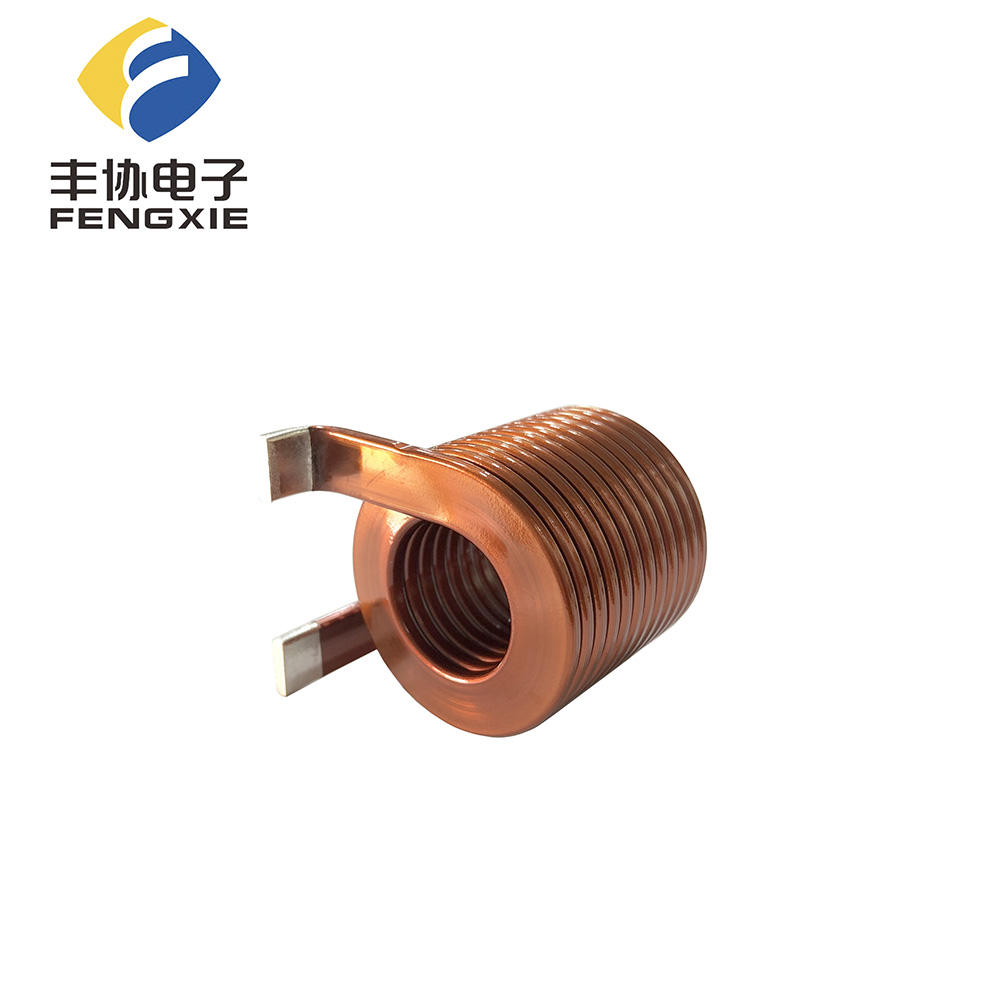

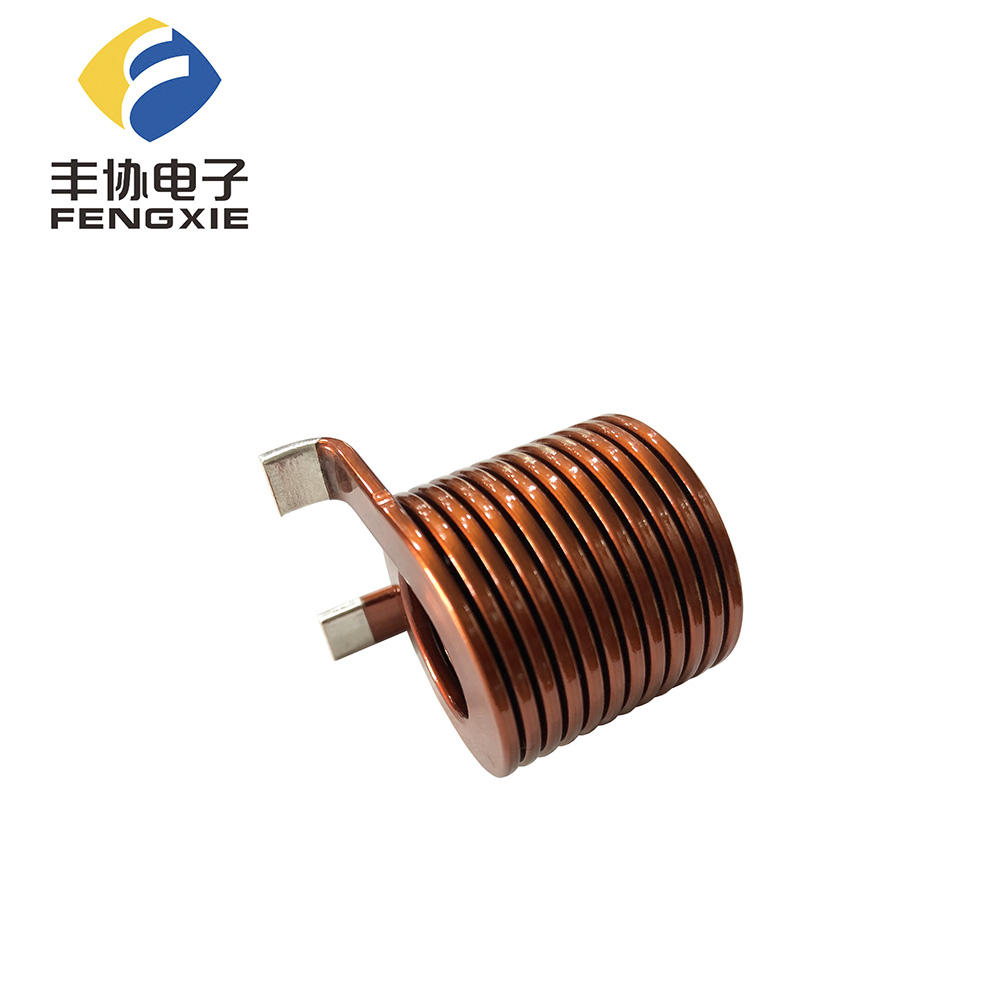

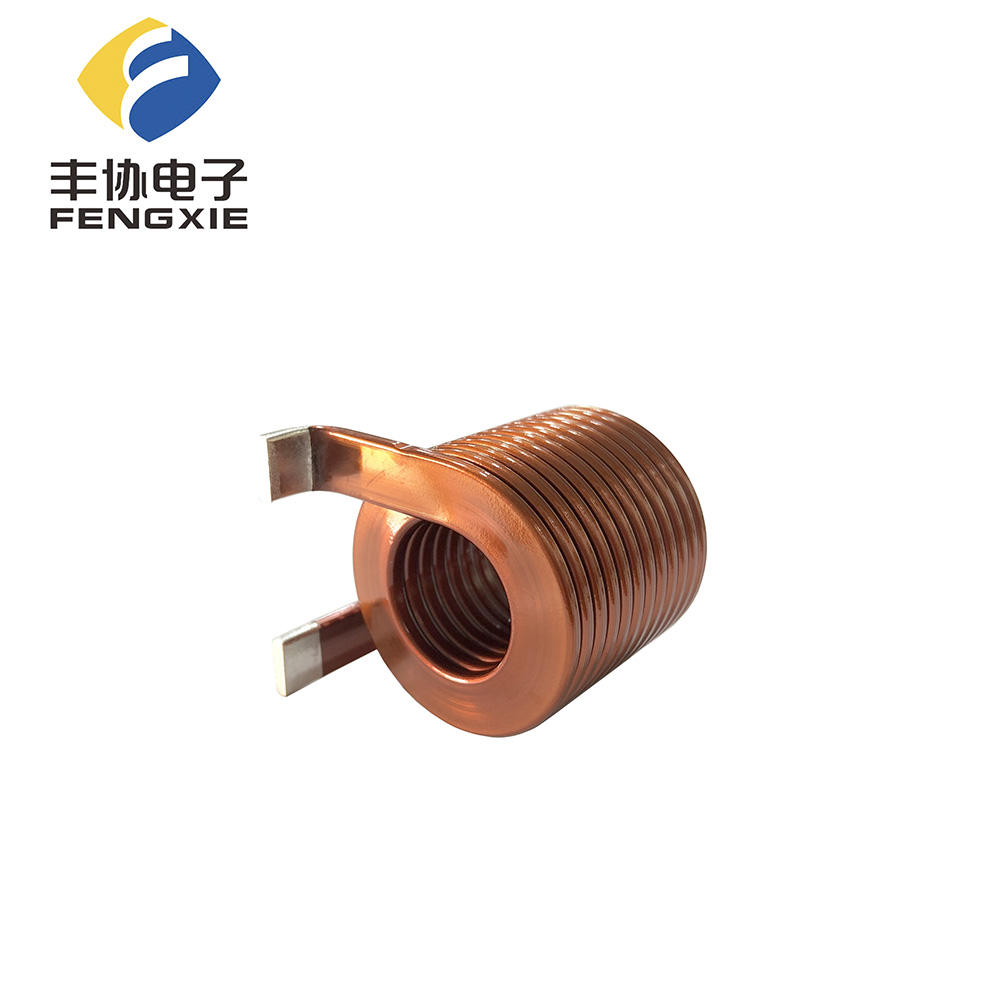

With the rapid development of electric vehicles, the performance requirements for components in automotive power electronic systems are becoming increasingly stringent. As one of the core passive components, the EV power inductor coil plays a crucial role in energy storage, filtering, and current regulation in automotive DC-DC converters. Especially with the trend of battery platform voltages evolving from 400V to 800V or even higher, DC-DC converters need to operate stably over an extremely wide input voltage range. Ensuring that the EV power inductor coil maintains a stable inductance value and effectively suppresses core saturation becomes the core of design success.1. High Power Density: Addressing High Current and Space ConstraintsElectric vehicle power systems are extremely sensitive to size and weight. DC-DC converters must handle peak currents of hundreds of amperes within a limited space. Therefore, modern automotive EV power inductor coils generally use high-saturation flux density materials wound with flat copper wire. Flat wires offer a larger surface area and lower AC resistance, significantly reducing temperature rise under high current. The edge-winding process ensures the conductor edges are perpendicular to the magnetic flux direction, further reducing eddy current losses. This high power density design not only improves energy storage capacity per unit volume but also effectively delays core saturation and maintains inductor stability under high current fluctuations caused by wide input voltages.2. Excellent Thermal Stability: Ensuring Consistent Performance Under Extreme ConditionsAutomotive operating environments range from -40°C to +150°C. Traditional magnetic materials are prone to permeability degradation due to thermal drift, leading to inductance decay. To address this issue, automotive-grade induction coils utilize cores with high Curie temperatures and low temperature coefficients, combined with high-temperature resistant encapsulation materials for overall potting. Furthermore, some high-end designs employ integrated heat sinks within a metal casing, directly coupling the coil to the cooling system. These measures ensure stable magnetic performance even under high loads, preventing nonlinear inductance changes or premature saturation caused by overheating.3. Low Magnetic Loss Design: Enhancing Efficiency and Reliability Across All Operating ConditionsWide input voltage means dynamic changes in switching frequency and duty cycle, easily triggering high-frequency core losses. To reduce iron losses, designers select low-loss ferrite or amorphous materials and optimize winding structures—for example, using multi-strand Litz wire to suppress the skin effect, or using segmented toroidal cores with Bobbin Wound Coil to achieve uniform magnetic field distribution. For high-frequency applications, even coreless structures can be used to completely avoid saturation risks. These low-loss strategies not only improve the overall efficiency of DC-DC converters but also reduce heat accumulation, indirectly enhancing the stability of the inductor across the entire voltage range.4. Robust and Reliable Structure: Resistant to Vibration and Mechanical ShockElectric vehicles continuously experience road vibrations and mechanical stresses from rapid acceleration/braking. Ordinary inductors are prone to winding displacement and core cracking, leading to abrupt changes or even failure. Therefore, automotive EV power inductor coils commonly employ laser welding, integral die casting, or high-strength bonding processes to firmly combine the core, frame, and terminals. Flat coils are more resistant to deformation due to their rigid structure, while toroidal inductors naturally possess low EMI and high mechanical strength due to their closed magnetic circuits. This type of design meets automotive-grade standards such as AEC-Q200, ensuring long-term reliable operation in critical systems such as BMS and traction inverters.