What are the unique advantages of PV inverter inductors in dealing with complex and ever-changing power grid environments?

Publish Time: 2026-01-12

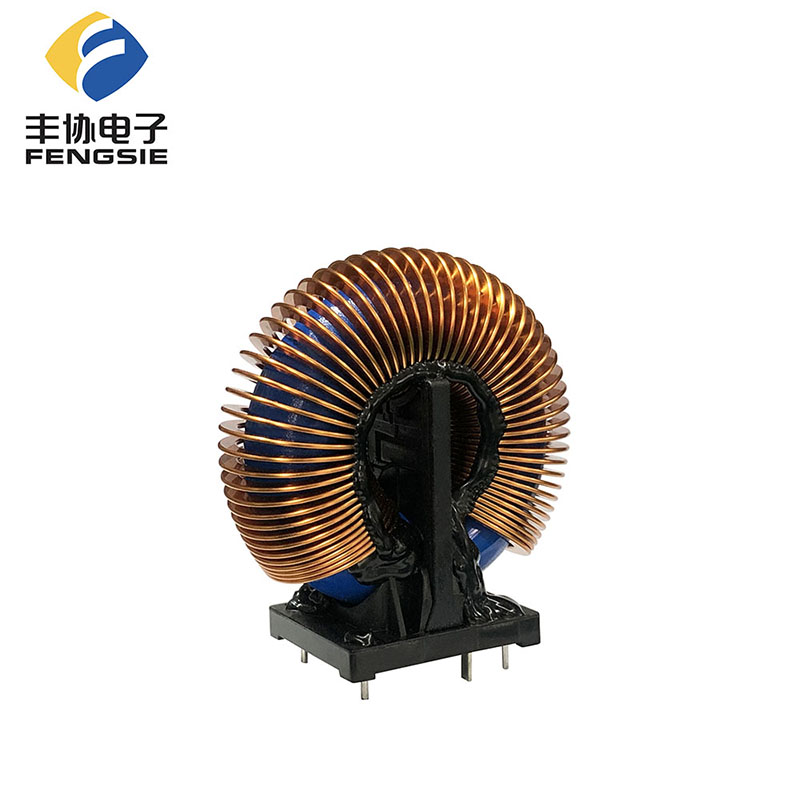

In photovoltaic (PV) power generation systems, the inverter is the core hub connecting the DC PV array to the AC power grid. PV inverter inductors—especially power inductors, toroidal inductors, and high-frequency chokes wound with flat copper wire—are key magnetic components ensuring the stable and efficient operation of the inverter. Facing complex operating conditions such as grid voltage fluctuations, frequency shifts, harmonic interference, and sudden load changes, these PV inverter inductors, specifically designed for PV inverters, exhibit irreplaceable advantages due to their low losses, high saturation current, excellent thermal management, and strong anti-interference capabilities, becoming "invisible guardians" that improve system robustness and power quality.1. Flat Copper Wire Structure: Achieving a Balance Between High Efficiency and High Power DensityTraditional round wire inductors are affected by the "skin effect" and "proximity effect" at high frequencies, resulting in a significant increase in AC resistance, leading to severe heat generation and decreased efficiency. In contrast, the flat copper wire coils widely used in PV inverters, due to their wide and thin cross-section, significantly increase the effective conductive area of the conductor, effectively suppressing high-frequency losses. Meanwhile, the flat wires can be densely arranged, increasing the winding fill factor and achieving higher inductance or greater current carrying capacity within the same volume. This design allows the PV inverter inductor to maintain low temperature rise and high efficiency in high-frequency switching environments of 20–100 kHz, not only reducing heatsink size but also contributing to the miniaturization and weight reduction of inverters.2. High-Saturation Core Material: Resisting Current Surges from Grid DisturbancesWhen a short circuit, voltage drop, or sudden load switching occurs in the grid, the inverter output current may surge instantaneously. If the PV inverter inductor core saturates, the inductance drops sharply, leading to overcurrent damage to the switching transistors. Therefore, photovoltaic power inductors generally use high-saturation flux density iron-silicon-aluminum, amorphous, or nanocrystalline cores, combined with optimized air gap design, ensuring unsaturation even at 1.5–2 times the rated current. This surge protection capability allows the inverter to maintain controllable output during grid anomalies and even supports low-voltage ride-through, meeting grid connection requirements.3. Toroidal Structure: Natural Electromagnetic Shielding, Reducing EMI InterferenceThe power grid environment is filled with various electromagnetic noises, and the inverter's own high-frequency switching also generates conducted and radiated interference. Flat-wire toroidal inductors, due to their closed magnetic circuit structure, have extremely low leakage flux, requiring almost no additional shielding to effectively suppress electromagnetic interference. This not only simplifies PCB layout but also avoids crosstalk to surrounding communication modules or sensors, improving the overall electromagnetic compatibility of the system.4. Multi-layer Winding and Integrated Design: Adapting to New Demands of Energy Storage and Smart GridsWith the rise of integrated photovoltaic and energy storage technologies, inverters need to handle photovoltaic input, battery charging and discharging, and grid interaction, resulting in more complex operating modes. New multi-layer flat-wire inductors can integrate multiple windings on the same magnetic core, used for DC-DC boost, bidirectional charging and discharging, or filtering, reducing the number of components and increasing power density. Simultaneously, some inductors incorporate temperature sensors or current sampling coils, providing real-time feedback to the digital control chip, enabling dynamic adjustment and precise response to grid dispatch commands.5. Reliable Packaging and Thermal Management: Ensuring Long-Term Outdoor Operation StabilityPV inverters are often deployed on rooftops, in deserts, or in high-humidity coastal areas, facing harsh environments. The PV inverter inductor utilizes high-temperature resistant insulated enameled wire and vacuum-impregnated epoxy resin or potting silicone processes, providing moisture resistance, dust resistance, and vibration resistance. The flat wire structure itself has a short heat dissipation path, allowing heat to be easily conducted through the PCB or metal base, avoiding localized hotspots and ensuring continuous operation for 25 years without failure in environments ranging from -40℃ to +85℃.In summary, the PV inverter inductor based on flat copper wire technology, through synergistic innovation in materials, structure, and processes, comprehensively surpasses traditional solutions in efficiency, reliability, interference immunity, and integration. It is not only a "stabilizer" for energy conversion but also a key cornerstone for inverters to adapt to future smart grids and the integration of high proportions of renewable energy—silently safeguarding the safe grid connection of every kilowatt-hour of green electricity.