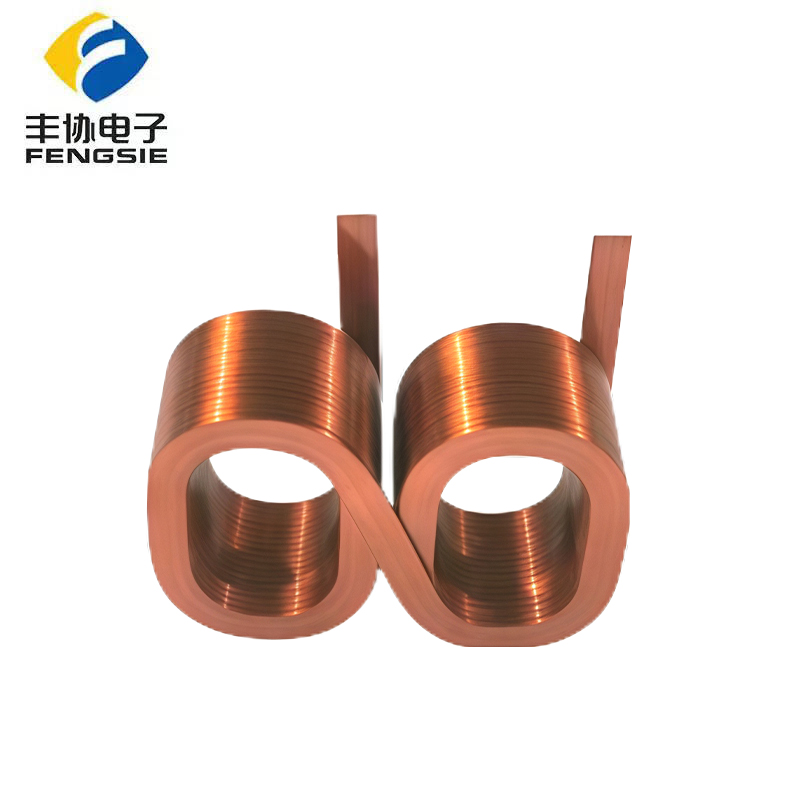

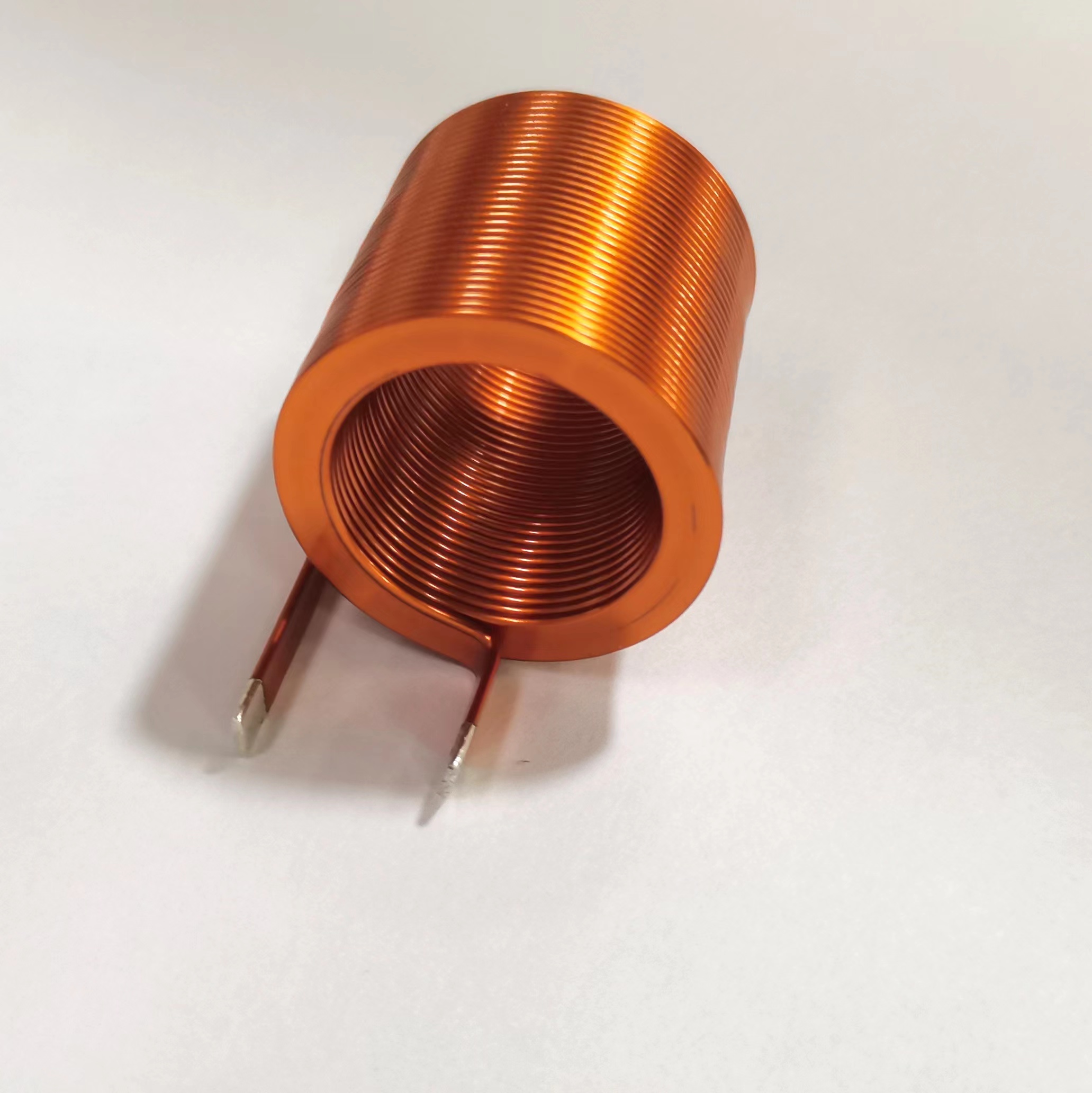

Redefining Magnetic Power, The Next-Generation Flat Wire Dual-Winding Coil

Publish Time: 2025-10-21

In modern power electronics, RF communication, and renewable energy systems, the design and efficiency of electromagnetic components have become critical competitive factors. As one of the core elements in electromagnetic energy conversion, the Flat Wire Coil – Dual-Winding Coil combines superior energy transfer performance, ultra-low magnetic core losses, and outstanding structural reliability. These attributes make it indispensable in photovoltaic energy storage systems, RF transformers, impedance matching networks, and wireless communication applications. This article provides an in-depth look at the engineering principles, performance advantages, application diversity, and future trends of this high-performance coil technology.I. Structural Innovation: The Fusion of Flat Wire and Dual-Winding Design1.1 Electromagnetic Advantages of Flat Wire GeometryConventional round wire windings often suffer from skin effect and proximity effect under high-frequency operation, causing uneven current distribution and increased AC losses. The flat wire geometry addresses these issues by enlarging the surface area in contact with the magnetic flux, achieving more uniform current flow and reduced frequency-dependent losses. Its customizable cross-section enables optimized space utilization and higher inductance per volume unit. This design not only enhances magnetic coupling but also meets the growing demand for compact and high-efficiency power components in modern systems.1.2 Electrical Flexibility of Dual-Winding ConfigurationThe dual-winding configuration introduces exceptional flexibility to circuit design. Through series, parallel, or differential connections, engineers can precisely tune inductance, coupling coefficients, and impedance matching according to specific system requirements. This allows the coil to operate efficiently in multiple modes, maintaining signal purity and stability even in high-frequency environments. In RF transformers and wireless power transmission modules, such dual-winding topology has proven to be essential for improving overall system efficiency and reliability.1.3 Structural Stability and Thermal ManagementThe wider cross-section of flat wire enables denser and more uniform layer stacking during winding. This geometry yields two major benefits: first, mechanical robustness, which resists deformation under high temperatures and vibrations; second, enhanced thermal conductivity, which accelerates heat dissipation from the winding core to the surrounding environment. The result is a coil that maintains stable operation under heavy electrical and thermal stress, making it ideal for high-power, long-life applications.II. Electromagnetic Performance: Engineering for Low Loss and High Efficiency2.1 Mechanisms Behind Ultra-Low Core LossMagnetic core losses primarily consist of hysteresis and eddy current losses. The flat wire dual-winding coil minimizes these through careful control of core material selection, air-gap distribution, and magnetic flux path design. High-permeability, low-coercivity ferrite or nanocrystalline materials are used to reduce hysteresis losses, while precise winding geometry suppresses eddy current loops. The result is a highly efficient energy conversion system with minimal magnetic dissipation.2.2 High-Frequency Power Transfer EfficiencyIn RF and wireless power transfer (WPT) applications, coils must operate efficiently at frequencies ranging from hundreds of kilohertz to several megahertz. Traditional round-wire coils face significant energy decay due to skin effects, while flat wire coils ensure lower AC resistance and improved high-frequency performance. The dual-winding structure further enhances energy coupling linearity and minimizes phase distortion or leakage inductance, thereby maximizing the system’s power transfer efficiency.2.3 Reliability and Electrical Insulation IntegrityAlongside performance, long-term reliability and insulation safety are key indicators of coil quality. Each flat wire dual-winding coil is manufactured using high-temperature enamel coatings and interlayer insulation films, preventing dielectric breakdown or aging under prolonged thermal and electrical stress. Winding spacing and geometry are optimized through electro-thermal coupling simulations to ensure stability even under high-voltage conditions. This level of reliability is why these coils have become a standard choice in industrial power supplies and renewable energy converters.III. Application Expansion: Bridging Photovoltaics, Communication, and Energy Storage3.1 A Core Element in Photovoltaic Energy Storage SystemsIn photovoltaic (PV) and energy storage systems (ESS), flat wire dual-winding coils serve as critical elements within DC/DC converters and inverters. Given the voltage fluctuations inherent to solar inputs, these coils must maintain stable magnetic characteristics under high-current, high-frequency operation. The flat wire ensures excellent thermal dissipation and current capacity, while the dual-winding topology allows designers to flexibly adapt to various circuit architectures—such as Buck, Boost, or LLC resonant converters. As a result, these coils contribute to higher conversion efficiency, reduced harmonic distortion, and extended inverter lifespan.3.2 Precision Role in RF Transformers and Impedance MatchingIn RF communication systems—including 5G base stations, satellite links, and high-frequency power modules—accurate impedance matching and energy coupling determine signal fidelity. Flat wire dual-winding coils, characterized by low insertion loss and high Q-factor, preserve waveform integrity and minimize phase deviation. By adjusting the coupling coefficient between the two windings, engineers can fine-tune specific frequency responses or implement custom filter characteristics. This precision makes them indispensable in next-generation communication hardware.3.3 Enhanced Efficiency in Wireless Energy TransferIn wireless charging and inductive power transfer systems, coupling efficiency and stability are paramount. Dual-winding configurations enable optimized primary-to-secondary magnetic coupling ratios, while the flat wire’s geometry increases magnetic flux density and minimizes leakage. Whether integrated into consumer electronics charging pads or electric vehicle inductive charging platforms, these coils deliver superior power transfer efficiency and compact system integration.IV. Manufacturing Excellence and Quality Assurance4.1 Precision Winding and AutomationProducing flat wire dual-winding coils demands high mechanical accuracy. Advanced CNC-controlled winding systems ensure precise layer stacking, tension control, and inter-turn alignment. In dual-winding designs, symmetry and spacing between layers are carefully maintained to achieve uniform magnetic distribution. Automation not only enhances consistency but also minimizes human error—ensuring every coil meets rigorous technical standards.4.2 Materials and Surface Treatment TechnologiesHigh-performance flat wires are insulated with polyimide or FEP coatings for superior thermal endurance and oxidation resistance. The magnetic cores are treated with epoxy or nanocoatings to prevent mechanical stress concentration and moisture degradation. For dual-winding products, multi-layer insulation films and epoxy encapsulation techniques are employed to ensure long-term durability even in extreme operating conditions.4.3 Testing, Validation, and Quality ControlEvery coil undergoes comprehensive testing—covering inductance, Q-factor, dissipation factor, insulation voltage, and high-temperature aging performance.

Leading manufacturers also use magnetic flux simulation and X-ray structural inspection to verify winding integrity. This all-encompassing quality system ensures that each coil performs reliably in demanding industrial and renewable energy applications over years of continuous operation.V. Integration and Intelligent Design5.1 Digital Design and Simulation-Driven EngineeringWith the digitalization of power electronics, the design of flat wire dual-winding coils is shifting from empirical approaches to multi-physics simulation models. AI-driven optimization algorithms now allow engineers to predict electromagnetic, thermal, and mechanical performance simultaneously. This simulation-driven design methodology accelerates product development cycles while ensuring superior performance consistency and longer service life.5.2 Toward Modular and System-Level IntegrationThe future of energy conversion lies in modular and integrated architectures. Instead of existing as standalone components, coils will form part of holistic energy modules alongside magnetic cores, PCBs, and capacitors. The flat wire dual-winding coil’s geometric adaptability and flexible connectivity make it a natural fit for next-generation modular inverters, on-board chargers (OBC), and power conditioning systems.5.3 Advancing into High-Frequency, High-Power Density DomainsAs SiC and GaN wide-bandgap semiconductors drive switching frequencies higher, power systems demand coils with superior magnetic and thermal properties. Flat wire dual-winding coils, with their low AC losses and excellent heat dissipation, are emerging as the optimal choice for high-frequency, high-power-density applications. They are set to play a pivotal role in the evolution of efficient, compact, and intelligent energy architectures.